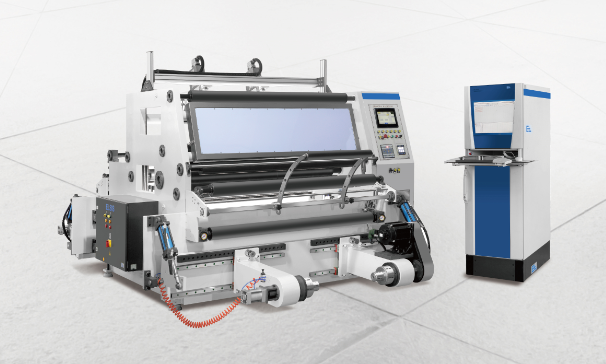

在线检测平台

|

Jumbo roll width |

放卷最大宽度 |

1400mm |

|

Diameter of roll |

放卷最大直径 |

Ø800mm |

|

Diameter of rewind |

收卷最大直径 |

Ø800mm |

|

Inner dia. of paper core |

纸管或塑料管内径 |

3'' |

|

Mechanical speed |

机器速度 |

300m/min |

|

Total power |

整机功率 |

15kw |

|

重量 |

4500kg |

1. 性能和特点:

该机器主要适用于检测BOPP,PET,CPP,PVC铝箔或纸张表面的印刷瑕疵检测。

2. 主要配置:

1. 牵引: 安川伺服电机1套

2. 收卷:安川伺服电机1套

3. 放卷:安川伺服电机1套

4. 放卷纠偏采用台湾品牌

5. 放卷和收卷采用无轴液压提升,独立的伺服电机控制张力

6. 放卷和收卷压辊采用电机加气缸的原来,由PLC集中控制,实现恒定压力

7. 整机采用PLC集中控制

8. 自动模式:当在线检测系统检测到瑕疵点,机器自动停机,并且倒转到瑕疵点,操作员人工剔除

9. 半自动模式:当在线检测系统检测到瑕疵点,机器不停,检测系统自动记瑕疵点到系统中,等整卷料走完,集中剔除

2. Performance and Characteristics:

1. Main Motor: 1 pc servo motor with pulling roller.

2. Rewind motor: 1 pc servo motor.

3. Unwind motor: 1 pc servo motor.

4. Automatic EPC for unwind.

5. Equipped with shaft-less for unwind and rewind's material loading. unwind and rewind's tension are from separate servo motor.

6. Pressure roller for rewind and unwind to make rewinding roll more uniform.

7. Machine's totally controlled by PLC.

8. Automatic mode: When a defect is detected, the machine reduces its speed until it stops rewinding, than the film is automatically rewound back and the defect area stops over an inspection plate for visual examination.

9. Semi-Automatic mode: When a defect is defected, the machine does not reduce the speed, it will save the data with photos in the computer and keep inspection after rewinding is finished, when the inspection is done, the computer will show all the defect details and photos, when click the defect through by the computer, the machine auto rewound back and the defect area stops over an inspection plate for visual examination.